| Virtual Instrument | ||||||

| Mould | Foundry | StampForming | Reverse Engineer | Sheetmetal | RapidPrototyping | Thermo |

ESI ProCAST 2022 for Windows 64bit

ESI ProCAST 2021.5 for Windows 64bit

ESI ProCAST 2019 for Windows 64bit free download

ESI ProCAST 2018 for Windows 64bit free download

ESI.ProCAST 2016 for Windows 64bit free download

ESI.ProCAST 2015 for Windows 64bit free download

ESI.ProCAST 2014.5 for Windows 64bit free download

ESI ProCAST v2014.0 & Visual-Environment v9.6 free download

ESI.ProCAST 2009.1 free download

ESI.ProCAST 2008 free download

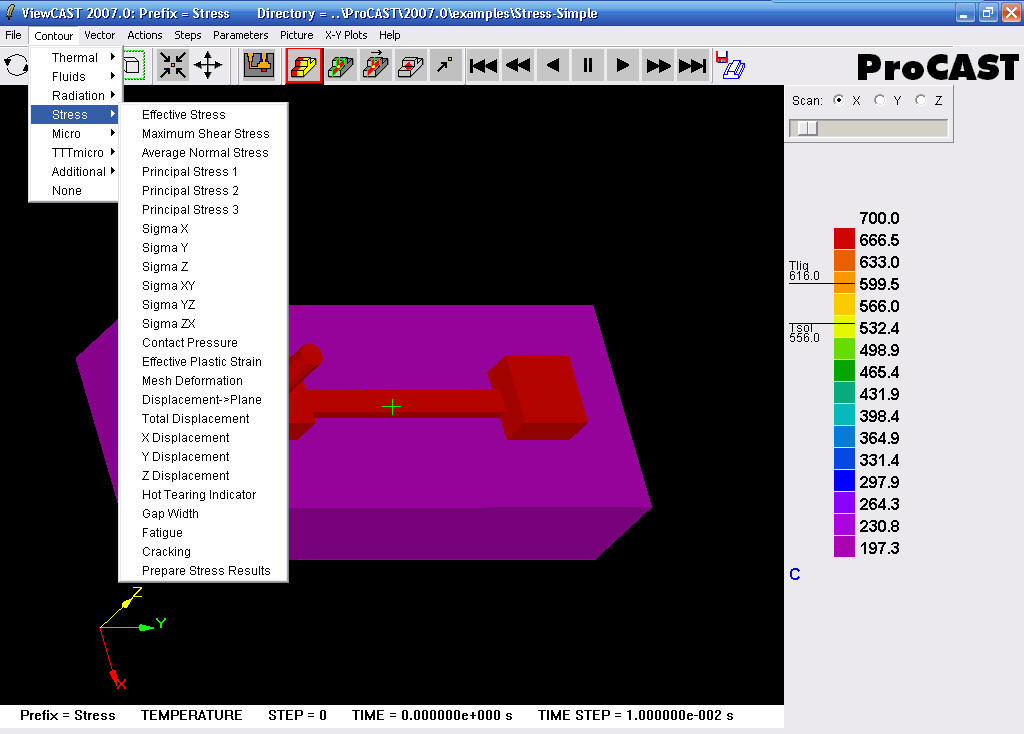

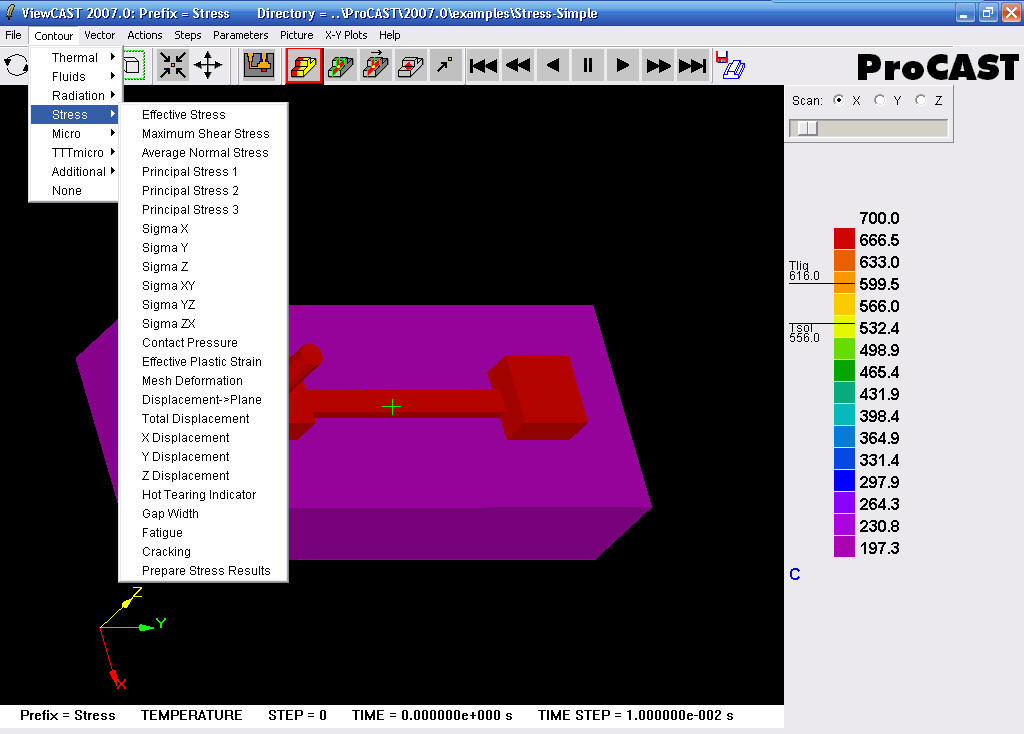

ESI.ProCAST 2007 free download

ESI.ProCAST v2006

ESI.ProCAST v2005

ESI.ProCAST.v2004

ESI.ProCAST.V3.0

ESI.ProCAST.V3.1

ESI.ProCAST.V3.2

Simulation allows cast parts manufacturers to test their casting processes fully virtually, and to do this early in the process development cycle. Accurate prediction and quantification of defects and process design are imperative to ‘get it right’ during production trials.

With ESI’s proven casting simulation software ProCAST, you can cast your parts right the first time, every time – meeting your deadlines and never wasting money on scrap parts or late redesigns. For decades, customers have relied upon ProCAST as their go-to tool for the casting basics – filling, solidification, and porosity prediction.

Boasting advanced physics and Finite Element technology, it also predicts complex issues including deformations and residual stresses and comprehensively addresses most castable alloys and casting processes such as sand casting, die casting, investment casting, and their multiple variants.

MAIN ProCAST USER BENEFITS

MAIN ProCAST APPLICATIONS & PREDICTED DEFECTS

Casting Simulation

ESI.Procast

SYSWELD

VA One

FLOW-3D

CFD-ACE+